How to Design Removable Batteries for the EU Battery Regulation (EU) 2023/1542

July 1, 2025

Engineering Value and System Role of Medical TDM: Why Medical Device Manufacturers Choose Atemitech’s Display Module Solutions

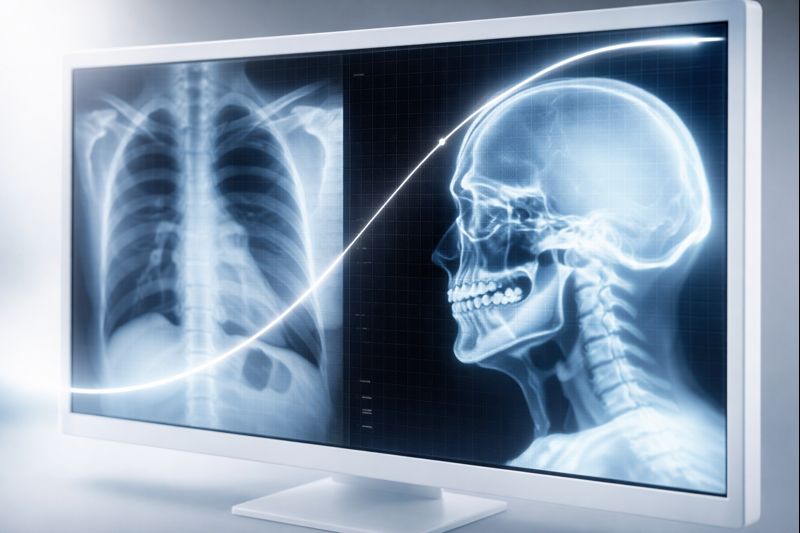

February 12, 2026In the rapidly evolving landscape of medical technology, medical tablets and display terminals have transitioned from simple "information displays" to critical tools for Computer-Aided Diagnosis (CAD) and high-precision surgical applications.

For leading medical device brands pursuing excellence, the primary challenge in selecting a display provider lies not in the initial "unit cost" of a module, but in the four hidden costs that emerge throughout the product lifecycle: diagnostic inaccuracies, maintenance overhead, hardware-software integration complexities, and the risks associated with regulatory compliance and supply chain instability.

Leveraging deep R&D expertise and clinical insights, Atemitech delivers high-caliber solutions that empower clients to elevate their products from standard display terminals to professional diagnostic-grade standards.

1. The Hidden Cost of Diagnostic Errors: From Precision to Consistency

In radiology and pathology, physicians rely heavily on the natural transition of grayscale for accurate interpretation. Any inconsistency in image performance across different batches or devices poses significant clinical risks and potential legal liabilities. The Atemitech Solution: DICOM Part 14 Professional Pre-calibration Standard commercial displays often fail to meet medical grayscale requirements. Atemitech provides built-in calibration services compliant with the DICOM Part 14 standard, ensuring every unit delivers a quantified and objective luminance response. Value Creation: Atemitech helps leading brands position their Touch Display Modules (TDM) directly in the diagnostic market. By ensuring every shade of gray meets clinical requirements, we mitigate the cost of misdiagnosis at the source.2. Reducing Maintenance Costs from Performance Decay: SBC (Sensor-based Brightness Control)

Medical devices often operate 24/7, making LED backlight decay an inevitable physical reality. However, diminishing brightness directly compromises diagnostic quality, forcing hospitals into shorter replacement cycles—a long-term maintenance burden for brands. The Atemitech Solution: SBC (Sensor-based Brightness Control) Technology Atemitech’s proprietary SBC technology utilizes integrated sensors to monitor backlight intensity in real-time, executing automatic compensation through advanced control circuitry. Value Creation: This significantly extends the product longevity. Even after 3–5 years of intensive use, the display maintains its original factory-calibrated brightness, eliminating the hidden costs of frequent manual recalibration or premature equipment decommissioning.

3. The Development Cost of Integration: Proprietary Scaler Boards & Deep Customization

Off-the-shelf controller boards often fall short in specialized scenarios, such as endoscopic surgery, where the ability to distinguish between various shades of red and tissue pink is critical. The Atemitech Solution: In-house Scaler Board Design & Firmware Customization With the capability to design proprietary Scaler Boards, Atemitech can modify Gamma curves and color temperatures at the firmware level. Image Optimization: We optimize for high chromaticity and contrast in bright operating room environments while effectively eliminating light leakage. Value Creation: Brands no longer need to compromise with generic hardware. Atemitech’s Integrated Display Solutions (IDS) ensure seamless synergy between the panel, driver, and touch interface, drastically accelerating Time-to-Market (TTM).4. Risk Costs of Certification & Lifecycle Management: A Commitment Beyond Supply

Obtaining medical certifications (such as ISO 13485, IEC 60601-1, IEC 62133) is a multi-year investment. The greatest risk is a core component (Panel or Driver IC) reaching End-of-Life (EOL) shortly after launch, which often triggers an expensive and time-consuming re-certification process. The Atemitech Solution: Medical-Grade Longevity Service & Comprehensive Documentation Atemitech regards "Long-term Supply Management" as a core competency: 5-10 Year Stable Supply Guarantee: Long-term lifecycle planning for core medical components. Regulatory Support: Providing complete RoHS/REACH declarations, traceability records, and technical files to expedite client certifications. Value Creation: Atemitech absorbs the risks of supply chain volatility. For our partners, this translates to minimal re-certification costs and maximized brand trust.