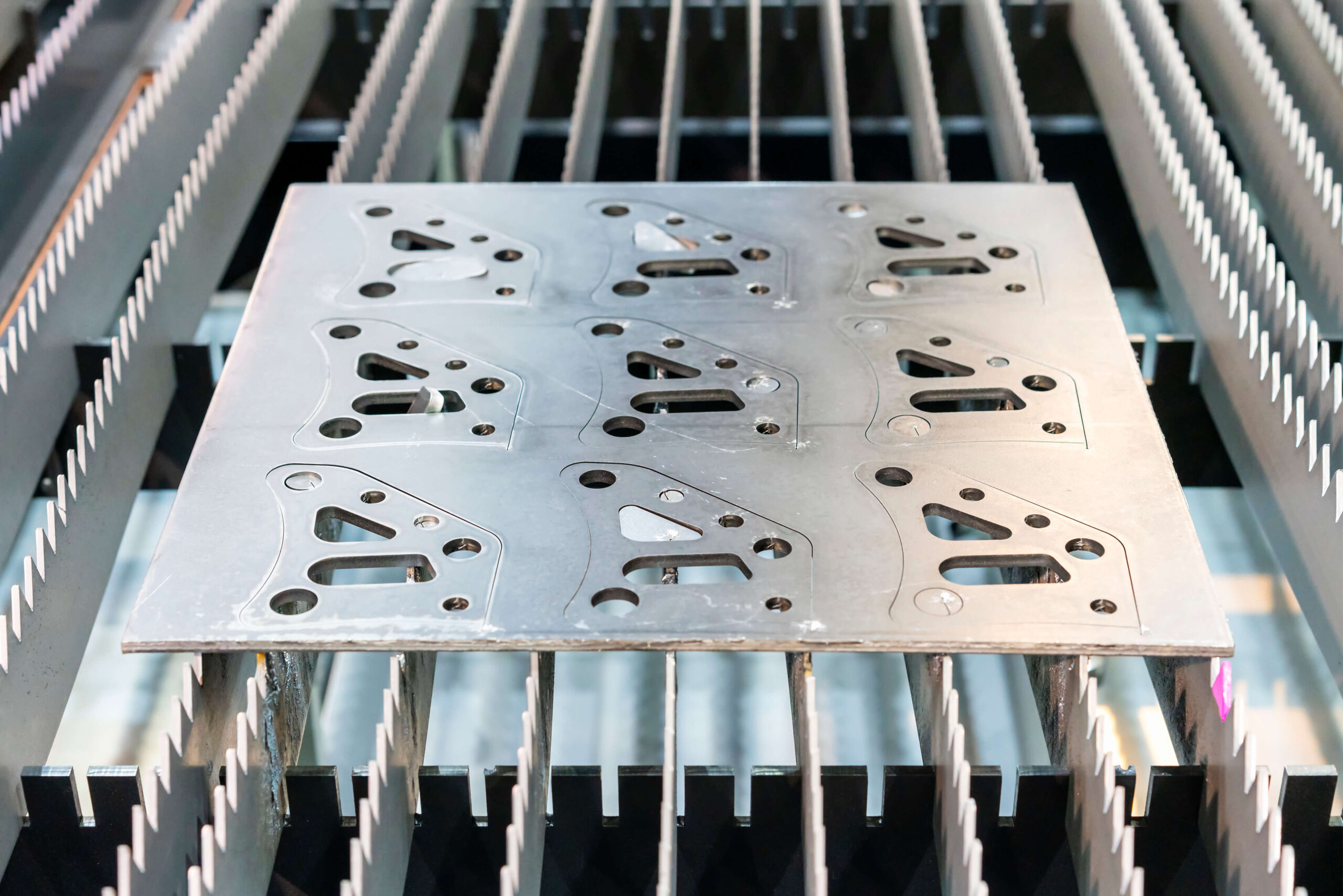

We provide high-precision sheet metal fabrication services including sheet metal design, roll out, laser cutting (or NCT blanking), folding, welding to surface treatment (plating, powder painting, water painting, printing), all completed in the factory to ensure quality and timely production.

Unlike contemporary molding technologies that is limited to small quantity prototypes only, Sheet metal fabrication is suitable for prototyping, batch production or even large-scale production. Customers can take the advantage of soft tooling in the initial product development stage for product verification to shorten the formal tooling cycle and also reduce the risk of design changes.

We possess excellent technology and process capabilities.

Whether it is POP riveting and welding assembly, insert molding, or overmolding, we can meet the diverse needs of customers.

Desktop computer chassis

Server chassis (1U - 6U)

Chassis for storage facilities

Vehicle mount for automotive Sensors

Housing for EMI Shielding

Material Options

Finished Options:

Tolerance

| Tolerance | mm |

| Bends | +/- 0.3mm |

| Offsets | +/- 0.2mm |

| Hole Diameters | +/- 0.1mm |

| Edge to edge/hole; hole to hole | +/- 0.2mm |

| Hardware to edge/hole | +/- 0.2mm |

| Remarks |

|

Feature separated by two or more bends: +/- 0.3mm

Product Size

*The product specification is for general design purpose. For any specific design purpose or project requirement, Please contact our sales representative to find out alternative process options.

Maximum Size:

Part size 2400mm*1200mm, bend length 2000m

Minimum Size:

Part size 2400mm*1200mm, formed part 3mm