Overview

3D printing, or additive manufacturing, has the benefit of automatically, quickly, directly, and accurately converting computerized 3D designs into physical models.3D printing technology also applies in the manufacture of parts and molds to effectively shorten the product development cycle.

We provide different 3D printing technologies following the perfect processes and materials to make prototypes according to your needs.

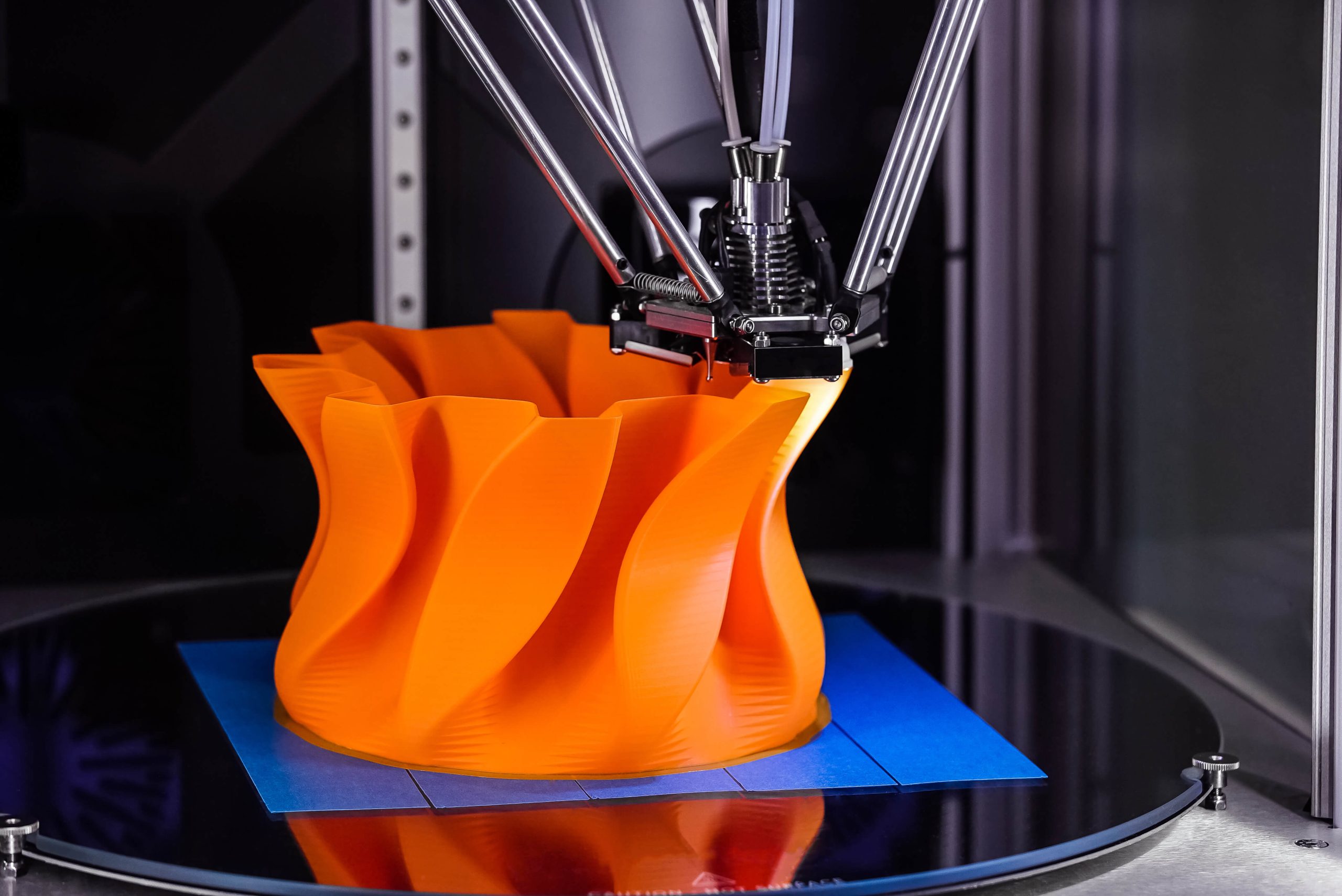

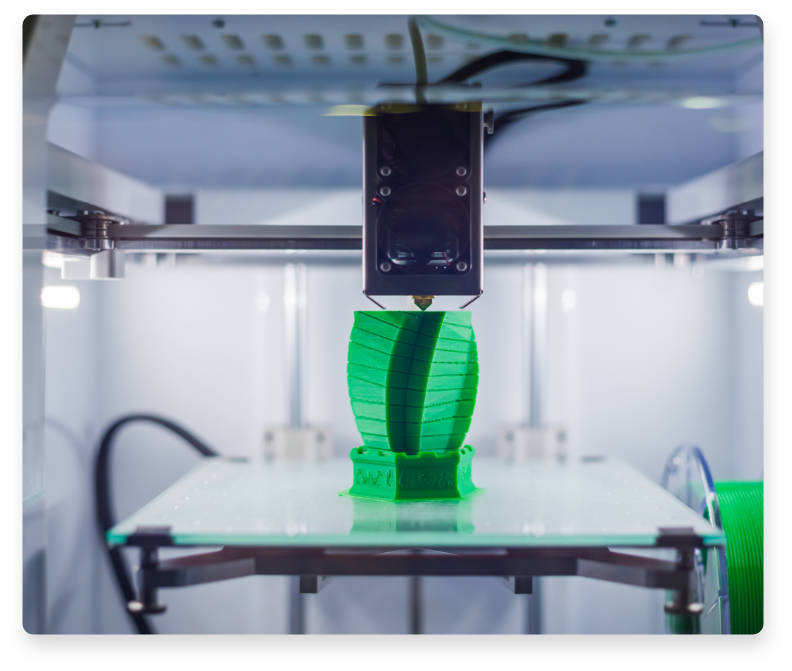

3D printing is a widely used process known as Fused Deposition Modeling (FDM). FDM printers use a thermoplastic filament, which is heated to its melting point and then extruded, layer by layer, to create a three-dimensional object.

Materials like ABS and PLA are commonly used for FDM, particularly for the manufacture of functional prototypes and production parts in aerospace, automotive and medical industries.

Get a Quote

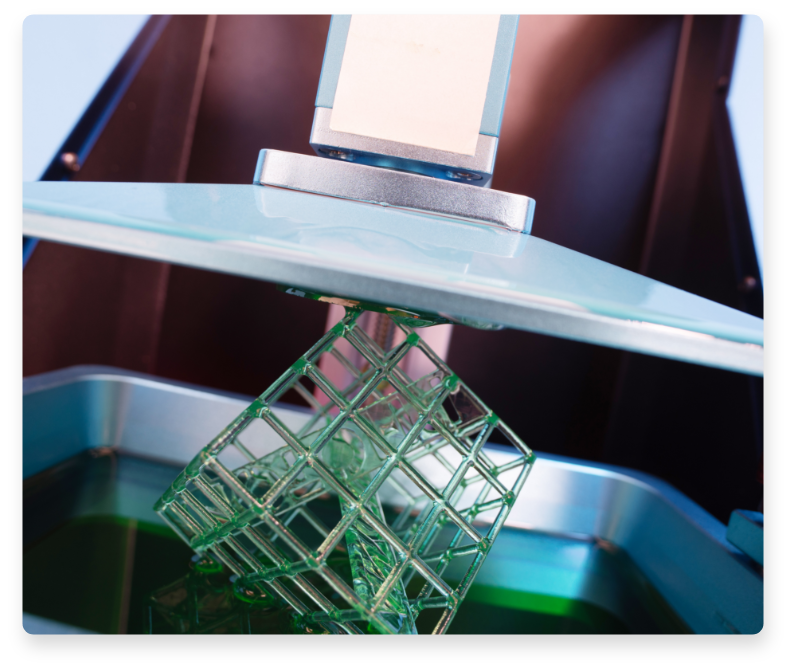

Stereolithography (SLA) irradiates the photosensitive resin through a laser light source to make it solidify. During the printing process, the laser spot moves on the liquid surface of the photosensitive resin continuously, and the final product is produced through layer-by-layer curing and stacking.

Stereolithography can be applied to a variety of materials, with the highest processing accuracy. The surface forming is relatively smooth and detailed, making this process most suitable for the manufacture of transparent objects or mass production.

Get a Quote

Direct Metal Laser-Sintering (DMLS) uses a high-energy laser beam, controlled by 3D model data to partially melt the metal matrix, while sintering and solidifying powdered metal materials and automatically stacking them layer by layer to generate dense geometrical solid parts.

DMLS has the advantages of lower chance of deformation, good strength, no holes, no defects such as inclusions and cracks. The mechanical strength is also great, similar to the injection molding product, and it can be used immediately after printing

DMLS has a wide range of materials choices. Commonly used materials are tool steel, aluminum, titanium and nickel in the manufacture of prototypes and production parts in the industrial, medical and aviation sectors:

Get a Quote

Material Options for 3D Printing