Flexible, Responsive, Professional Service Teams

We have excellent engineering team to provide customers with high-quality, high-precision mold prototypes, while committed to saving customers costs, shorten the time to market. The exact delivery date for each order depends on the order pipeline and production scheduling at that time, but in most cases we try to deliver the finished product to our customers within a certain period of time as long as the order request does not involve unique or complex designs requirements. In general, 3D printing part can be finished in as fast as one day, an urethane casting part in approximately 4-5 days, CNC machining part in 4 days, and, sheet metal fabrication part can be finished in 4 days.

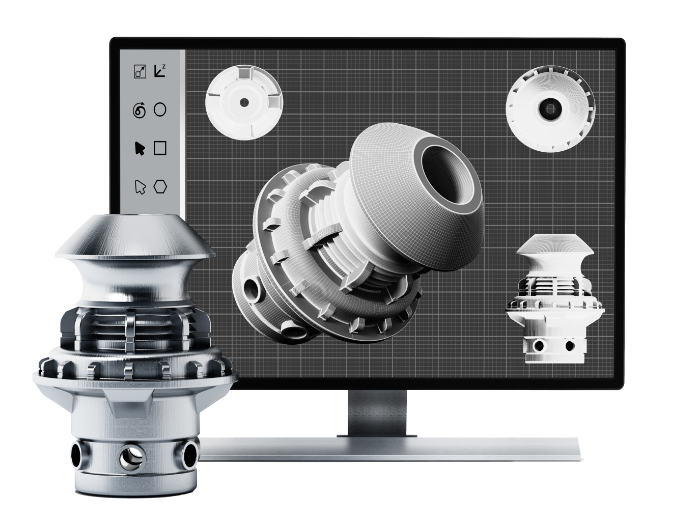

In-House Capability in Seamless Transfer of Production Technologies

Atemitech is an internationally affirmed mechanical solution provider, affording one-stop mechanical solutions, ranging from mold prototype, mold designing, tooling, plastic injection, to surface processing such as coating, printing, and assembly for delivery, all of which are performed in-house. If customers wish to incorporate the mold prototype in production, we can do so immediately as requested, thus shortening the process of transfer from mold prototyping to mass production.

Pioneer of Technology Innovation

We have established a professional research and development team and a CNAS-certified professional laboratory. We devote resources to the research of new materials, and has accumulated considerable technical experience in the applications of glass fiber and carbon fiber materials. In addition to new material studies, Atemitech is devoted to process innovation, we can offer a diversified choices of process technologies and surface treatments to our customers to create lighter, thinner, more environmentally friendly, and more fashionable mechanical products.

Up-to-date Manufacturing Facilities and Equipment

To meet customers’ diverse needs for material quality and external design, our plants are equipped with all types of processing equipment for advanced plastic and metal modeling, to afford complete range of model production and surface processing technologies, including computer-assisted engineering (CAE) technical support, CNC cutting sheet metal forging, molding, and assembly, silicon mold placing, soft mode, surface processing, and product assembly and delivery services.